JAKARTA – A number of media in Morocco, reported that STMicroelectronics will soon inaugurate the production of EV chips at the facilities of the French-Italian joint venture in Bouskoura, an industrial city on the outskirts of Casablanca. STMicroelectronics' Bouskoura plant has already started some initial production for Tesla in June 2021 with the existing line.

Morocco's production of EV chips will help alleviate the global shortage of automotive microchips experiencing crisis. The brand is also helping EV automakers to maintain their production schedules in the fast-growing electric car market.

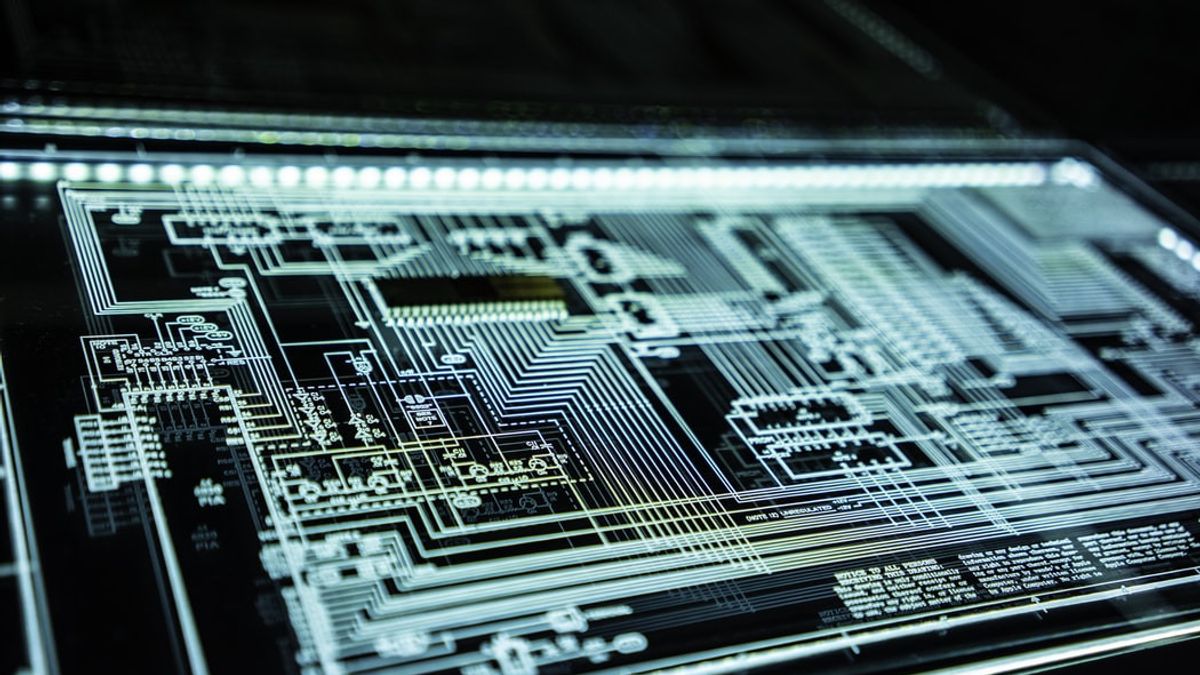

An electronic microchip is an integrated circuit (IC) printed on a very small semiconductor. These semiconductor ICs, commonly referred to as "chips", form a fundamental component of all electronic devices and have driven economic growth and innovation through the digitization of goods and services.

Cars are no exception to the trend - a typical contemporary car uses over 1,400 semiconductor chips. Engaged in the design, manufacture, and sale of IC products, STMicroelectronics is Europe's largest integrated software manufacturer with automobile chip components accounting for 38% of annual revenue before COVID.

Global Supply Crisis

5G rollout, requires semiconductors with the same node size and larger as automated chips. In addition, the increasing use of artificial intelligence and the development of the Internet of Things, have created a surge in demand for chips. The conditions have put supply pressure on automakers around the world.

The post-COVID-19 global supply crisis in chips has led to a significant slowdown in auto production. General Motors and Ford Motor, for example, predict revenue cuts in 2021 by more than US$2 billion and US$2.5 billion, respectively, due to supply delays.

SEE ALSO:

This shortfall has highlighted the auto industry's dangerous dependence on Asian semiconductor manufacturers, which has ultimately prompted US and European automakers to step up their efforts to find alternative sources of supply.

Demand pressures are further exacerbated by the growing popularity of electric passenger cars, which are on track to become the dominant form of mobility during the 2030s. Next to the electric battery itself, the chip is perhaps the most vital part of an EV. Today the electric car industry requires far more chips than internal combustion engine (ICE) cars.

Electric cars also require a large number of semiconductor ICs for their battery management systems to ensure safety by regulating the electric power circuit and optimizing the energy efficiency of battery charging and usage.

The declining supply of chips has caused car manufacturers in Japan such as Suzuki, Nissan, and Mitsubishi to limit their car production. Luckily in Indonesia, this crisis can still be overcome.

Director of Administration, Corporate and External Relations of PT Toyota Motor Manufacturing Indonesia (TMMIN) Bob Azzam said that Toyota's car assembly plant in Indonesia has not been affected by the shortage of semiconductor chips. "Until now it has not been affected," said Bob.

Seeing this need, the chip factory, Bouskoura STMicroelectronics is here to solve a number of chip supply problems. Meanwhile, the plan to build a chip factory in Indonesia has reportedly not materialized. The United States (US) semiconductor chip maker GlobalFoundries has announced that it will build a new factory in Singapore. This factory is also expected to meet the world's global chip demand, which is currently hit by scarcity.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)