BALIKPAPAN - A State-Owned Enterprise (BUMN) PT Waskita Beton Precast (WSBP) built two special batching plants (readymix) to serve projects in the capital city of the archipelago (IKN).

"Since January 2023, we have been a subsidiary of the First BUMN Karya to establish a batching plant to support development needs at IKN," said WSBP Corporate Secretary Fandy Dewanto, quoted by ANTARA, Sunday, November 19.

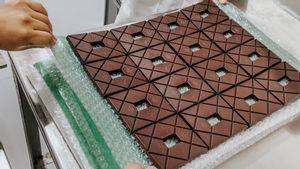

With a production capacity of 78 cubic meters per hour, the Sepaku Batching Plant (BP) can produce a quality Fc 10 to 35, Fs 45, and K100-K350 production volume of 1,716 cubic meters per day. Through BP Sepaku WSBP, it supplies readymixes for various government building projects, road access, to drinking water transmission.

Fandy, to date, the supply progress for the Presidential Secretariat Building Development project and the Supporting Building of the Indonesian Presidential Palace Area is 57.12 percent, the supply for the Coordinating Ministry for 3-4 Building Project is 39.44 percent, the IKN KIPP Ring Road/Logistic Project for the Sepaku Segment 4 Ring Road is 80.20 percent, the KIPP IPAL Project (Limbah Water Processing Installation) is 94 percent, the Phase I National Aquaculture Road Project is 44.40 percent, the Development Project for the Transition Network for Drinking Water Transmission is 81 percent %, and the East and West Side National Aquaculture Road Project is 63.43 percent.

There are also two new supply contracts, namely the IKN Feeder Road Project (District) which has run supply of 2 percent, and the ASN Flats Development Project of 1.8 percent.

The total progress supply of BP Sepaku for these projects is 57.69 percent with a total contract value of all projects of Rp286.97 billion, explained Fandy.

Another project supplied by WSBP is the Simpang Tempadung-Jembatan Toll Road Project on Balang Island Section 5A with a contract value of IDR 76.51 billion. For this project, WSBP provides a quality readymix of Fc 10, Fc 15, Fc 20, Fc 30, Fc 35, and Fc 50 of BP Tempadung with a production capacity of 56 cubics per hour and a volume of 1,232 cubics per day. Fandy added that until now the progress supply of this project has reached 35.09 percent.

In addition, for this 6.675 km toll road project, WSBP also provides quality PC-I girders from WSBP with specifications of a length of 40.8 m and a height of 2.1 m totaling 48 spans made directly at the precast plant in East Java, namely Plant Prambun which has a total production capacity of 425 thousand tons per year.

"Currently, production and delivery have been completed, directly from Plant Prambun via sea via Tanjung Perak Port, Surabaya and have arrived at HK pier, Balang Island, Tempadung, East Kalimantan," said Fandy.

With the support of batching plants and adequate resources, Fandy is optimistic that all orders to supply the project can be completed on time.

Later, WSBP will also see opportunities to target other projects at IKN, such as flat projects, hotels, and other public facilities.

"Currently we have raw material support in Palu so that it makes it easier to supply materials for readymix production in batching plants," said Fandy.

WSBP is also conducting a study of the opportunity to establish temporary plants and has collaborated with local suppliers in Palu to ensure the supply of raw materials for the IKN project, thereby increasing the opportunity for WSBP to achieve various projects at IKN. This strategy is carried out as an effort to support IKN completion and increase the use of domestic content (TKDN) for this project.

The hope is that through this project, WSBP can continue to contribute to development at IKN Nusantara with all quality precast and readymix products. In addition, in the process, WSBP always maintains and implements good corporate risk management and Governance in order to obtain projects that do have a good level of financial health.

On the other hand, according to Fandy, WSBP is not only building in terms of infrastructure, but is committed to having a positive impact on the social community and the environment in IKN Nusantara and its surroundings.

This is a manifestation of SDG's (Sustainable Development Goals) commitment which was realized in the WSBP Inspiring Kindness program on October 25-27.

The program carried out is 9 m3 readymix material assistance for the repair of the 10 m long Bukit Raya Village Road in Sepaku District and assistance for the construction of the Hafidz-Hafidzah Uswatun Khasanah House covering an area of 9\times11 m in Penajam. This program is WSBP's commitment to SDGs No. 9 namely Industry, Innovations, and Infrastructure.

There is also a support program for orangutan conservation in the form of funding donations for food for 127 orangutans and 71 sun bears at the Samboja Lestari BOSF rehabilitation center. This program is in line with SDG's No. 15 regarding Life on Land.

In addition, to implement SDG's No. 6, namely Clean Water and Sanitation, WSBP realized the provision of equipment for clean water sanitation purposes in two locations, namely Sukaraja Village and Datuk Nondol Village in Sepaku District.

"In the sanitation program in Sukaraja Village, we invite PT Permodalan Nasional Madani (PNM) Balikpapan Branch to collaborate to realize the availability and proper clean water and sanitation management," said Fandy.

VOIR éGALEMENT:

Other collaborations are manifested in the mangrove seed planting program of 4000 on Balang Island, East Kalimantan. This is one of the responsibilities of WSBP to preserve its environment in accordance with SDG's No. 15 regarding Life on Land.

"This whole series of WSBP Inspiring Kindness activities on the island of Kalimantan is a good trace from us for the people of Kalimantan and their environment," said Fandy.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)