JAKARTA - Currently the main focus of the United States Space Agency (NASA) is preparing for a human landing mission on the Moon or dubbed Artemis. This mission is targeted to launch in 2023 or 2024 at the latest.

Citing NASA's official website, Thursday, September 16, work on a spacecraft called Orion for Artemis I is almost complete, and Artemis II is going well.

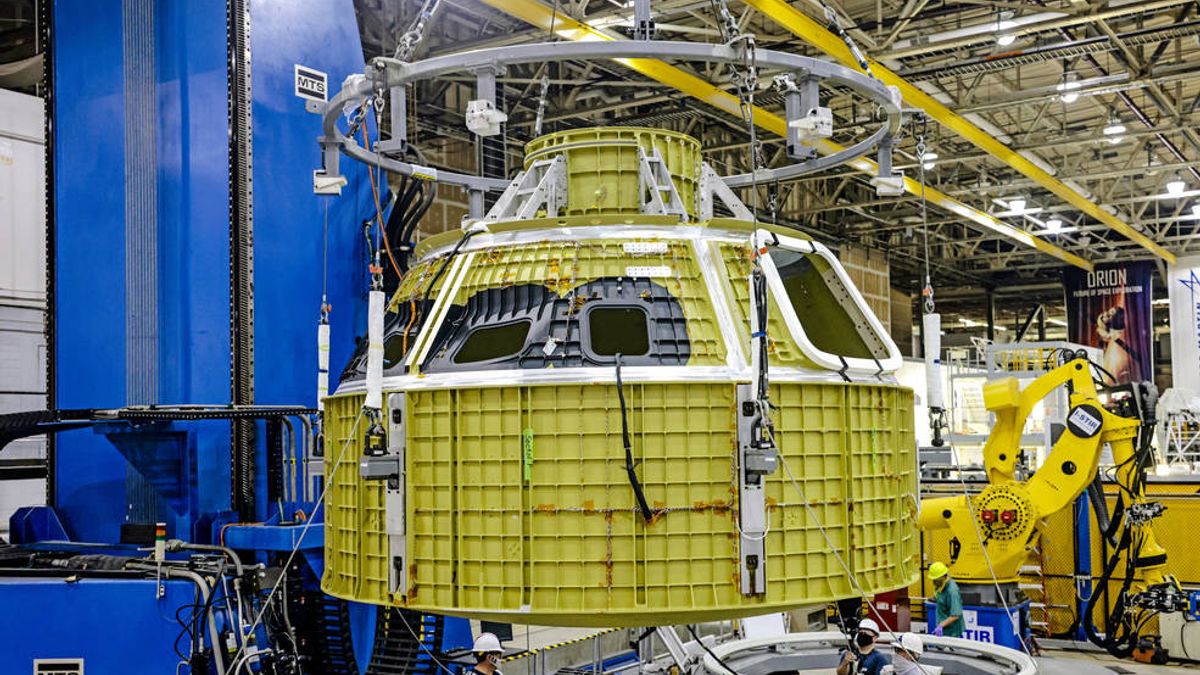

Now the Space Agency recently completed welding on the pressure vessel of the Orion spacecraft for the Artemis III mission, the basic framework of an airtight capsule for astronauts called the crew module. This structure is the first major piece of hardware in the Orion production phase with prime contractor Lockheed Martin.

"NASA is shifting its focus from the development phase to the production phase for the Orion spacecraft to enable a long-term presence on and around the Moon," said Orion program manager Cathy Koerner.

The development phase which includes design, testing and evaluation (DDT&E) is when the requirements for how the Orion aircraft are determined. The system also undergoes rigorous testing.

“All the intensive testing we have done has proven the Orion's structural design. A well-understood and well-defined structure gave us great confidence to move forward into the production phase," said Orion's chief program officer, planning and control, Stu McClung.

Every Orion component has undergone thorough testing since the inception of DDT&E to prepare for this transition. These included conducting Exploration Flight Test-1, Orion's first flight test in 2014 that demonstrated its spaceworthiness in high Earth orbit, and testing the spacecraft's heat shield upon entering Earth's atmosphere as well as the capsule recovery system.

Even NASA has also successfully completed testing of the Orion parachute system, as well as the launch cancellation system with two test flights known as Pad Abort-1 and Ascent Abort-2. Tests of the simulated in-space environment also verified that the Orion system would perform as expected during the Artemis mission, among many other spacecraft tests.

The DDT&E phase will officially close with the Artemis II mission, the first test flight with a crew. While no structural changes to the vehicles are expected to come from Artemis I and II, mission results could prompt minor changes or upgrades to the next build.

In the production phase, engineers will apply improvements to the Orion design to ensure that manufacturing and assembly are as efficient as possible. One of the many improvements is to reduce the number of weld pieces that make up the Orion pressure vessel.

The original pressure vessel design had 33 welded sections, simplified to seven for Artemis I missions and up, thereby increasing manufacturing capability and saving over 700 pounds of excess weight.

With seven recently completed welds on the Artemis III pressure vessel performed at NASA's Michoud Assembly Facility in New Orleans, resulting in structural design changes, testing completed, a more efficient and streamlined production line for the spacecraft began.

Under the Orion Production and Operations Contract (OPOC) awarded to Lockheed Martin, NASA will order a minimum of six and a maximum of 12 Orion spacecraft. The agency ordered three Orion spacecraft in 2019 for the Artemis III through V missions, and plans to order three additional Orion capsules in fiscal 2022 for the Artemis VI to VIII missions.

“Our strategy for moving from design and development to production focused on optimization by making changes in different areas to come up with a more efficient flow,” said Kelly DeFazio, program director for production operations at Lockheed Martin.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)