JAKARTA - The first and only Superabsorbent Polymer (SAP) producer in Indonesia, PT Nippon Shokubai Indonesia (PT NSI) built a third factory to maintain Acrylic Acid's domestic supply which continues to increase as well as increase the export market potential.

"For this reason, the Ministry of Industry (Kemenperin) appreciates PT NSI for expanding investment by PT NSI as the only company in Indonesia and Southeast Asia to produce Acrylic Acid and Acrylic Esters," said Plt. Director General of Chemical, Pharmaceutical and Textile Industries (IKFT) of the Ministry of Industry Ignatius Warsito in his official statement, Thursday, May 25.

PT NSI is the only company in Indonesia and Southeast Asia to produce Acrylic Acid and Acrylic Esters, as well as the first and only Superabsorbent Polymer (SAP) producer in Indonesia.

Acrylic Acid and Acrylic Esters are intermediate chemicals whose utilization is very wide, such as for raw materials in the emulsion, polymer and resin, acrylic fiber, and polioleffin copolymer industries. Meanwhile, SAP is used as an absorb material in disposable baby diapers or disposable diapers.

Nippon Shokubai Group owns 20 percent of the world's market share for SAP products, thus making Nippon Shokubai Group the world's largest supplier of SAP.

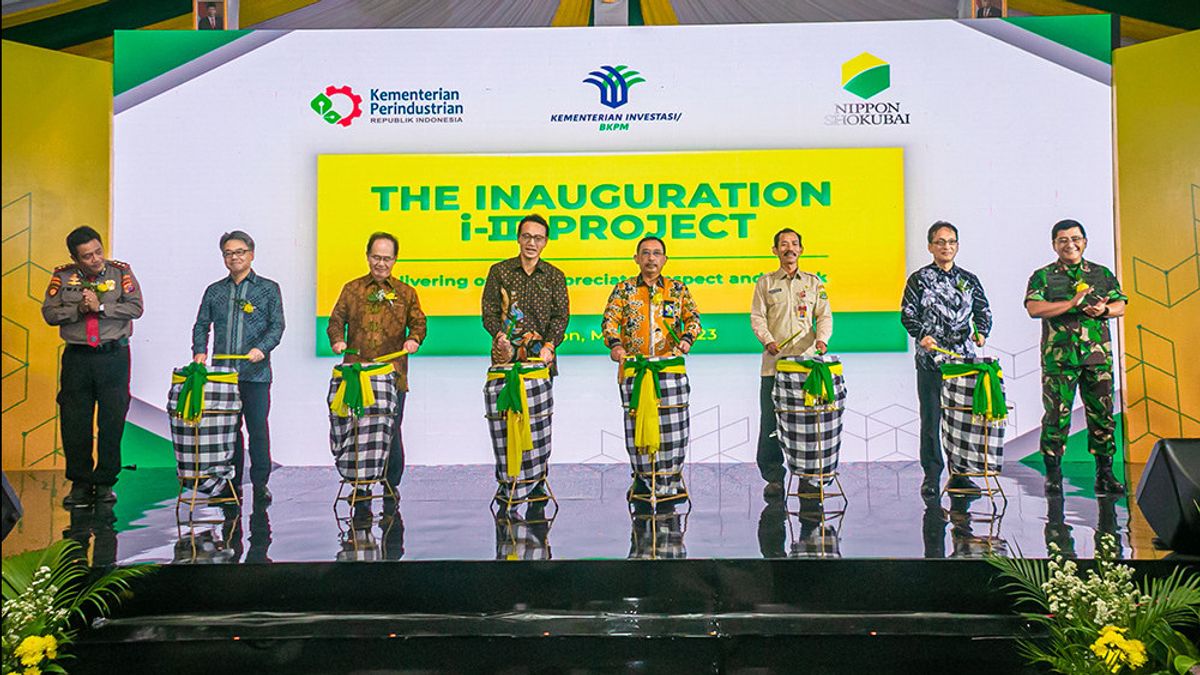

The investment in the third phase of the Acrylic Acid PT NSI project in Cilegon, Banten, shows that the potential for developing the intermediate chemical industry is very large.

With the addition of Acrylic Acid product capacity of 100 thousand tons/year, the total Acrylic Acid capacity of PT Nippon Shokubai Indonesia is 240 thousand tons/year. The addition of this production capacity contributes to maintaining domestic supply in anticipation of increasing domestic Acrylic Acid demand, as well as increasing export market potential.

The total investment value of 693 million US dollars to date has made PT NSI able to absorb skilled workers and open up new job opportunities.

"The Ministry of Industry will continue to strive to create a good, profitable, and sustainable industrial business climate through various policies, so that investment can continue to grow and Indonesia's economic strength will become stronger," said Warsito.

For your information, the chemical industry is the basic capital for industrial development downstream, such as the food and beverage industry, fabric fiber, textiles, packaging, plastic goods, electronics, automotive, and medicines. The success of national industrial development is influenced by the profile of the chemical industry.

また読む:

As a supplier of raw materials for the downstream industry, the chemical industry sector is expected to have adequate capacity and have good and stable performance at all times.

The importance of the chemical industry is shown by the magnitude of the contribution in GDP. Throughout 2022, the chemical industry is the third largest contributor to the non-oil and gas processing industry sector.

"This is what encourages the government to continue to strengthen the chemical industry through increasing production capacity and completing the structure of industrial trees to ensure the fulfillment of industrial raw materials," concluded Warsito.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)