JAKARTA - A British company led by former Made in Chelsea star, has successfully completed the first test of a rocket engine powered by plastic waste.

Pulsar Fusion, a Bletchley-based nuclear fusion company, successfully conducted tests at COTEC, a Ministry of Defense military base in Salisbury, November 17-18.

These plastic-powered rocket engines can be used for a variety of applications, including launching humans and satellites into space, according to Pulsar Fusion.

The company's main ambition is to produce high-speed propulsion engines using nuclear fusion technology for interplanetary travel – which could cut travel times to Mars in half.

They are currently working on a prototype nuclear fusion reactor designed to make plasma hotter than the sun's surface.

Tests last week showed a 'visually impressive plume effect' such as a supersonic diamond shock - the formation of a standing wave pattern - which is typical of high-temperature rocket exhaust.

The recent static test will be followed by an international demonstration for aerospace clients in Switzerland on November 25.

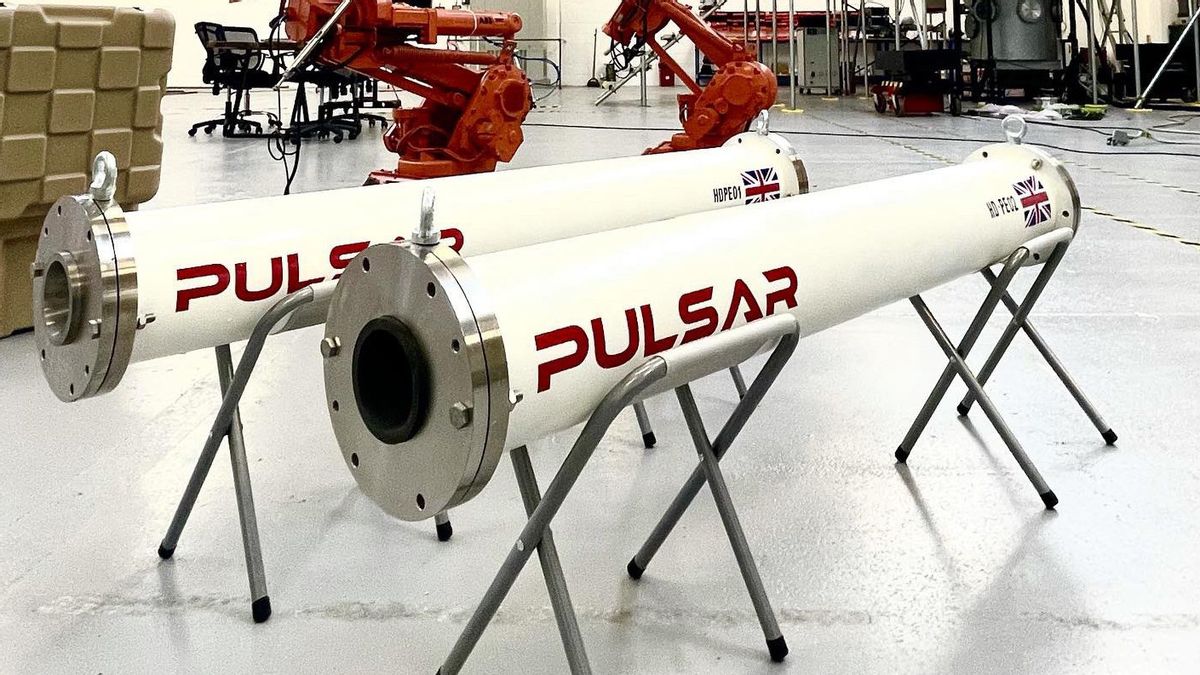

We test fired our first hybrid rocket engine earlier this week.

A great result for our first trials using HDPE/N2O fuels. pic.twitter.com/vsnVPDfzEm

— Richard Dinan (@RichardDinan) November 22, 2021

"Pulsar is one of the few companies around the world that has built and tested this technology," said Richard Dinan, 35, CEO of Pulsar Fusion, as quoted by Dailymail. "We have a fantastic team of scientists with a lot of experience to thank for this milestone."

"We've also attracted talent from some of the UK's top universities who have started working with and testing our plasma boosters on-campus facilities," said the Scientist, who has appeared on Made in Chelsea, a reality television show about the successful lives of young people in the UK, in 2012.

The rocket engine of the Pulsar Fusion is hybrid – meaning it uses rocket propellant in two different phases, one solid and the other either gas or liquid.

This 'green' rocket is supported by high-density polyethylene (HDPE), which can be obtained from recycling, and nitrous oxide. The two fuels burn together to produce non-toxic fumes.

HDPE can be found in recycled plastic so items can be used and recycled to produce powerful but non-toxic rocket fuel.

"Hybrid engines can run on recycled plastic, liquid engines can't," Dinan told MailOnline. "In terms of toxicity, it's very clean."

Plastic bottles and other waste can be melted down and thrown into cylinder blocks that are loaded into the rocket before each firing, he said.

SEE ALSO:

Dinan left school at the age of 16 and spent 10 years working as an entrepreneur before he began investing in nuclear fusion research in 2013, following his performance in Made in Chelsea.

He began hiring physicists to teach him thermonuclear physics, and has since taught at the University of Oxford.

Pulsar Fusion received UK government funding in September 2021 to further develop its 'hall effect thruster' plasma satellite engine, which is capable of generating particle speeds of 12.5 miles per second.

These Pulsar thrusters were recently tested at the Harwell facility where they were able to withstand 20g of vibration, in simulating a rocket launch.

The company's main milestone - to produce a high-speed propulsion engine for interplanetary travel using nuclear fusion technology - could be realized in just four years.

By 2025, Pulsar Fusion wants to develop a nuclear fusion propulsion engine for static demonstrations. Nuclear fusion for these reactors involves the use of powerful electromagnets to direct the reaction into a form of propulsion.

In 2027, Pulsar Fusion wants to manufacture a nuclear fusion rocket engine to launch and test in orbit. An extraordinary technological advancement because it utilizes waste that is categorized as toxic into rocket fuel.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)