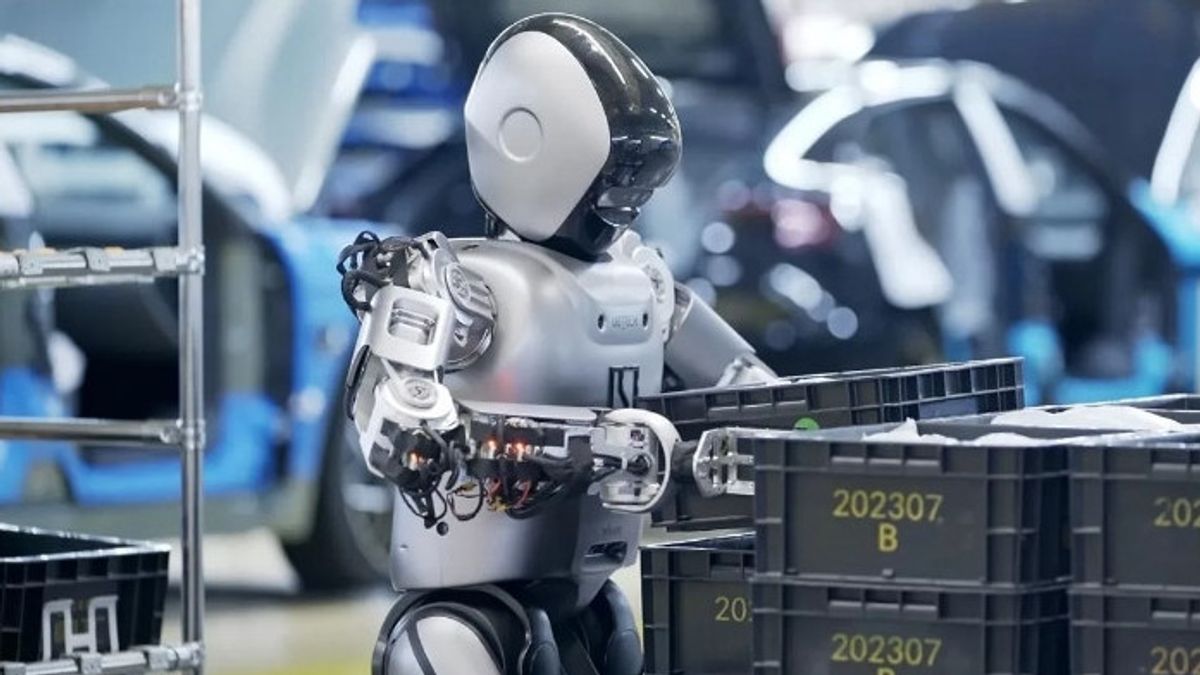

JAKARTA - Geely Holding Group's electric vehicle subsidiary Zeekr is experimenting with using humanoid robots at its factories, making it the second producer in China after Nio who did the same thing.

Citing the CNevpost page, Wednesday, August 7, the humanoid robot used is Walker S Lite from UBTech Robotics. This robot started operating in early July.

"To this day, Walker S Lite, UBTech's new lightweight product for the manufacturing and smart logistics sector, has worked at the Zeekr plant for 21 consecutive days," said the company's representative.

At the factory, a humanoid robot helps employees in the task of lifting, with a high level of work difficulties in the industry.

"The operation of humanoid robots at the Zeekr factory is the result of a collaboration between UBTech, Geely Holding, and Miracle Automation Engineering," the statement added.

Miracle Automation, an automated logistics system provider, announced on August 2 that it won a tender for Nio's main assembly line surveyor project F3-1, deepening cooperation between the two companies after the project at Nio's F4 plant.

Geely will provide an application scenario for the Walker S UBTech product and series solution, while Miracle Automation will provide production line data collection, process development, and scenario improvement design for humanoid robot training.

"The three parties will then work together to encourage the use of humanoid robots in automotive and component smart manufacturing scenarios," said UBTech.

SEE ALSO:

During training at the site for three weeks, Walker S Lite used a semantic Visual Simultaneous Localization and Mapping (VSLAM) navigation, thorough immitation learning, visual recognition, and fine movement control to navigate and run autonomously on different assembly lines, as well as in collaboration with automated guided vehicles (AGVs).

Interestingly, Walker S Lite, which is equipped with a high-performance servo driver and six-dimensional force sensor, can run stably while lifting a 15 kilogram box.

Zeekr is the latest electric vehicle manufacturer to experiment with humanoid robots at the plant, which is poised to further automate advanced production lines.

"This is the first time Walker S has had training at a new energy vehicle factory (NEV)," added UBTech.

At the Nio factory, Walker S takes advantage of real-time image retrieval and transmission capabilities to participate in checking the quality of the door lock, seat belts, front light cover, and being able to install the vehicle logo.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)