JAKARTA - The Ministry of Industry (Kemenperin) encourages the absorption of domestic ceramic products, including through spending based on the State Revenue and Expenditure Budget (APBN), so that national ceramic products can become hosts in their own country.

"One of the focuses of the Ministry of Industry is so that our national products can get certification quickly," said Minister of Industry (Menperin) Agus Gumiwang Kartasasmita in a written statement, Friday, February 24.

Minister of Industry Agus said, there are several regulations related to the obligation to use domestic products that his party continues to echo, including regulations on the addition of the value of the Domestic Component Level (TKDN) and the Company Benefit Weight (BMP) at least 40 percent.

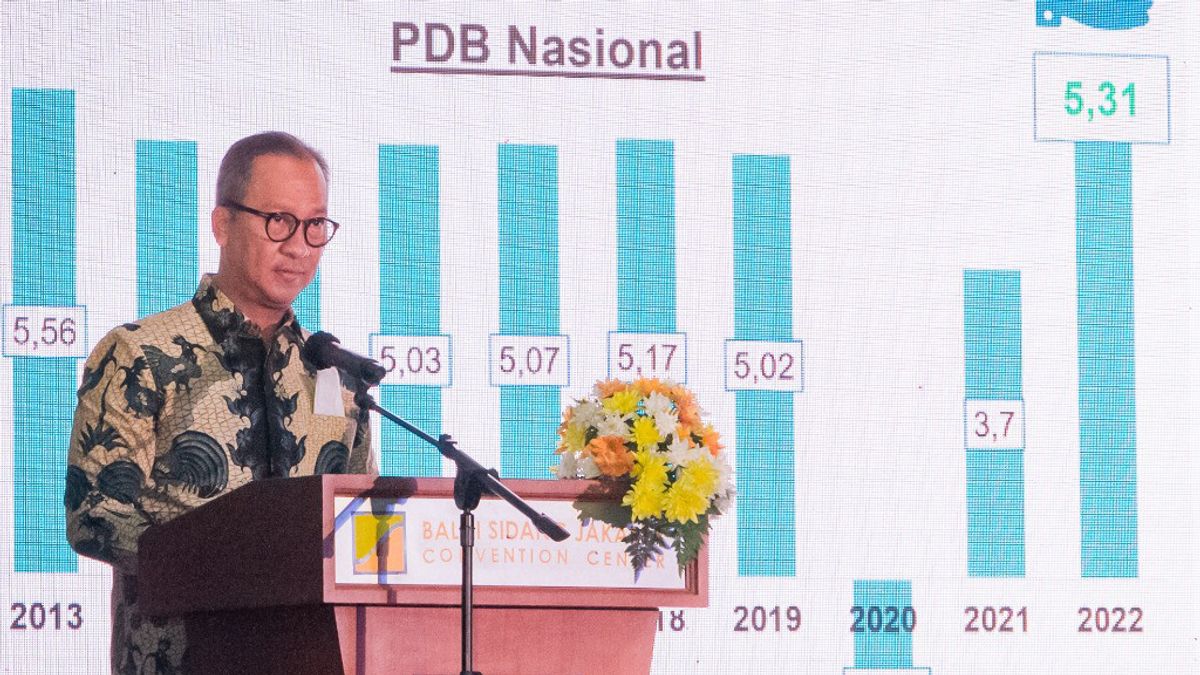

According to Agus, the national ceramic industry has bright prospects in line with the growing domestic market which continues to increase through the large number of government infrastructure projects.

One of the opportunities for developing the country's ceramic industry is supported by a potential government project, namely the construction of the capital city of the archipelago (IKN) which is currently underway.

"This is a great potential for the domestic industry, including for the ceramic industry and its supporters. Of course, we don't want IKN development to be filled with products that are not domestically based. So, I hope that the national ceramic industry roadmap will be able to meet the needs of IKN development," he said.

In the ceramic industry roadmap delivered by the Indonesian Ceramics Association (ASAKI), ceramic production of 551 million square meters was increased to 625 million square meters, then increased again to 810 million square meters to meet the target of ceramic use per capita numbers in Southeast Asian countries of three square meters.

If this target is met, it will make Indonesia the fourth largest ceramic producer in the world and the best in Asia.

"The Ministry of Industry will continue to assist and support this target. Moreover, the ceramic industry is targeted to achieve utilization above 82 percent until 2024. Currently, the utilization reaches 78 percent," said Agus.

Seeing the great development potential, the government has issued various policies to maintain conducive business climate sustainability, and continue to encourage the utility of domestic ceramic industry production.

One of these policies is the specific Earth Gas Price (HGBT) incentive for the industry at a price of 6 US dollars per MMBTU. The ceramic industry is one of the recipients.

"Perjuangkan kebijakan harga gas untuk industri sebesar 6 dolar AS per MMBTU ini tidak mudah. Namun, kami memegang prinsip no one left behind, agar industri nasional mendapatkan harga gas yang kompetif, sehingga produk-produknya akan jauh memiliki daya saing dibanding produk negara lain," ungkapnya.

According to Agus, the improvement in the competitiveness of the ceramic industry can also be achieved through the application of the principle of a green industry with environmentally friendly production. "Furthermore, what needs to be paid attention is to introduce new technology, so that products become high competitiveness and do not stop innovating," he said.

Agus added, although the domestic market still has high potential for the ceramic industry, his party continues to encourage the manufacturing sub-sector to see opportunities for export expansion to sustainable countries.

"I invite ASAKI to be more aggressive in penetrating the export market to countries that have the opportunity to become sustainable markets for ceramic products and their supporters," he explained.

Meanwhile, ASAKI Chairman Edy Sutanto appreciated the efforts of the Ministry of Industry to encourage the sustainability of the national ceramic industry. Through the various policies issued by the Ministry of Industry, the national ceramic industry is able to continue to expand, and recover faster after being hit by the COVID-19 pandemic.

Edy said that the Kemenperin policies had been felt as part of the solution to the problems faced by ceramic industry players, especially with the presence of an Industrial Activity Operational and Mobility Permit (IOMKI) which was proven to be very effective in the midst of the COVID-19 pandemic at that time.

"This policy gives us the flexibility and ability to operate normally. This is a greeting from 150 thousand employees who are members of ASAKI for an extraordinary policy," he added.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)