JAKARTA – During the 'Chipageddon' or global chip crisis, the Minister of Industry, Agus Gumiwang, proposed that semiconductor chips be produced in Indonesia. Agus said the plan was in accordance with the current development of industry 4.0. Agus assessed that to realize the plan, support from the government was needed regarding special policies and the ease of opening investment opportunities in the chip sector.

"To achieve this target, of course, government support is needed in the form of policies and facilities, both fiscal and non-fiscal. Providing incentives in the context of investment is one of the efforts to encourage investment in the semiconductor industry in Indonesia," Agus said in a virtual event as quoted by Antara.

The event, which was held online, was titled "Indonesian Industry Opportunities Regarding Global Chip Shortage Issues" on Tuesday, August 31, 2021 yesterday. The global chip crisis occurred in the midst of a pandemic that hit the world so that it could have an impact on a number of global automotive industry sectors, including Indonesia.

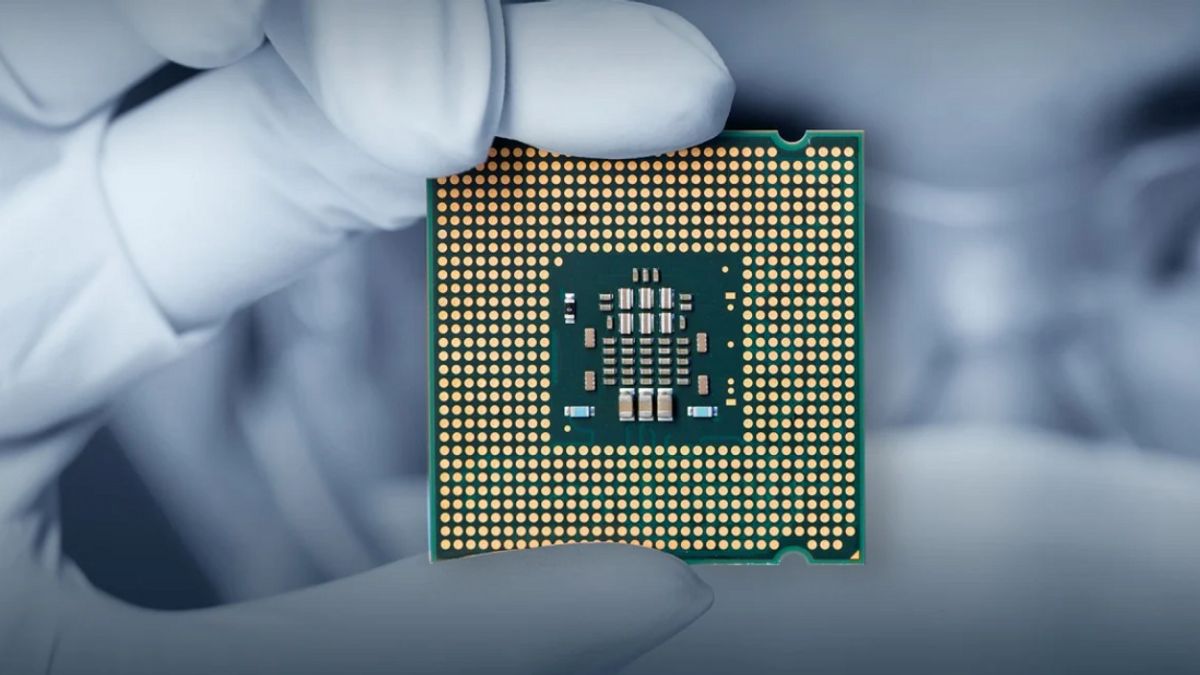

The pandemic has also forced a number of automotive factories to close, coupled with a limited supply of semiconductor chips. Chips are more widely used in electronic devices such as PCs, laptops, smartphones and so on. The high demand for chips is not matched by a small supply.

The chip crisis has also delayed a number of car manufacturers from delaying production. Therefore, it will take several years to establish a domestic semiconductor chip manufacturer. In addition, large investments and quality human resources are also required, considering the complexity of the design to chip manufacturing.

"This challenge provides new opportunities for Indonesian industry and start-up investors to contract manufacturing chips that are growing in various countries, especially the US, Japan, China, Taiwan, South Korea and European countries," said Agus.

In addition, the Minister of Industry also explained that in 1973 there was a semiconductor chip component company in Indonesia which was the result of the investment of two US companies, namely Fairchild Semiconductor and National Semiconductors. However, in 1985 the two companies had to leave Indonesia, so the country chose to import chips from abroad.

"With the Global Chip Shortage incident, we are now fully aware of how important it is to prepare a secure supply chain for the availability of domestic supply of semiconductor chip components," said Agus.

Agus also considered that currently chip manufacturing is not only controlled by one company. He said that currently it has been divided into several sections such as Fabless (Chip Design), IDM (Chip Design & Fabrication), Foundry (Chip Fabrication), and OSAT (Assembly & Test).

"Indonesia is eager to participate in the global semiconductor industry value chain through collaboration with various MultiNational Companies (MNCs) Partners and start-up companies around the world," said Agus.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)