JAKARTA - Taiwan Semiconductor Manufacturing Company (TSMC) is reported to be building a factory in Singapore, in this case the company is already in the discussion stage with the country's government.

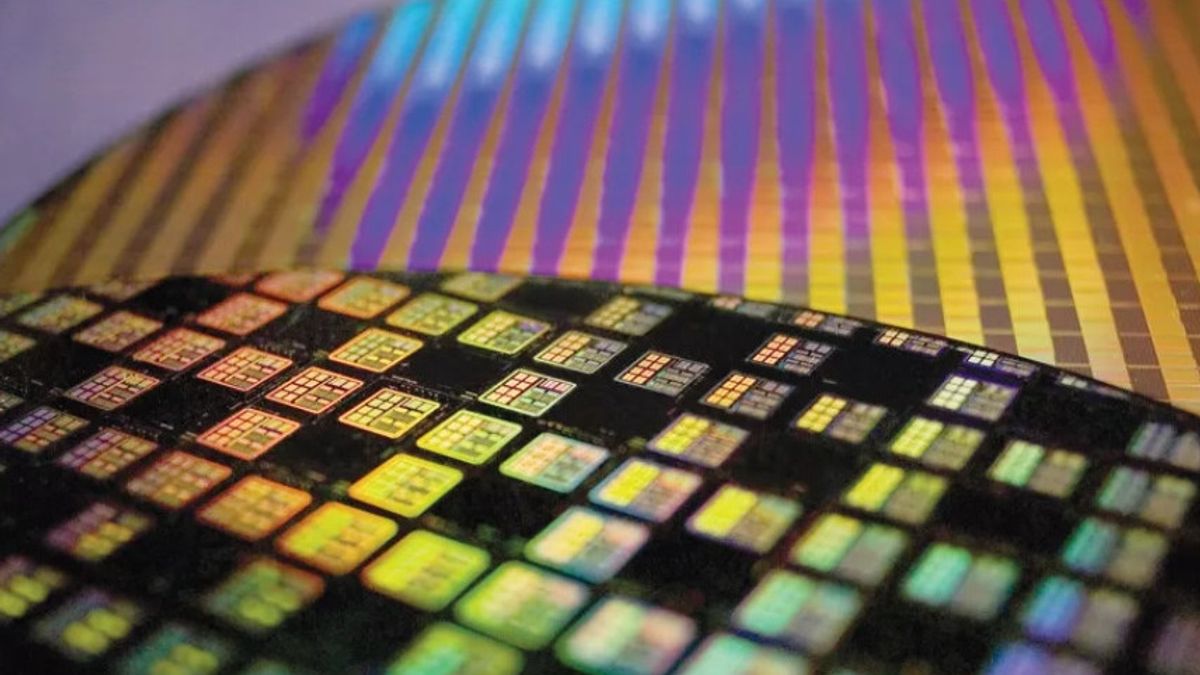

TSMC itself produces Apple's A-series and M-series chips, as well as AMD processors, but the tech giant also produces chips for display drivers and power management, which have been in limited supply due to the COVID-19 lockdown.

Those supply constraints have cost Apple $6 billion in the past two quarters, and that number could rise to $8 billion.

The Wall Street Journal reported that TSMC's Singapore factory will help address the supply shortage by producing more of the critical chip.

Currently, TSMC is also studying what a viable production line is for making chips from seven to 28 nanometers. It will be based on old production technology already used by cars, smartphones and other devices.

Even so, as reported by TechRadar, Friday, May 20, the new factory is still in the negotiation stage and has not been finalized until now. TSMC has other reasons for wanting a new plant in another country.

Companies will find it easier to work around China, and prevent too many chip production in one country. TSMC is also interested in building six plants in the United States (US), but has run into several snags this year since plans were first announced.

However, opening a factory in Singapore would further aid global diversification, while potentially avoiding what TSMC founder Morris Chang has described as a shortage of manufacturing talent in the US as well as the high cost of manufacturing chips.

TSMC is not alone, while Quanta Computer, the sole supplier of high-end MacBook Pro models, has also considered moving production from Shanghai to the Chongqing plant to help ease supply constraints as well, so TSMC is not the only supplier to Apple looking to diversify its production in the market. respond to supply chain crises.

Previously reported, TSMC also plans to increase the price of their chips between 5 percent to 9 percent in early 2023. The cost of producing chips has increased due to the supply crisis and logistics and materials are more expensive.

As the price of TSMC services increases, that means the prices of mobile phones and computers to data centers and connected cars also increase. It is known that TSMC also experienced a slight price increase in 2021, and it is a major chip supplier to giants such as Apple, AMD, Intel, and Nvidia.

With these price increases, it is claimed the peak of the imbalance in semiconductor supply or demand appears to have been missed, suggesting that the chip shortage could be resolved by the end of 2022.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)