Schneider Electric with the Indonesian Food and Beverage Manufacturers Association (GAPMMI) announced its cooperation in developing digital expertise for human resources in the food and beverage industry (mamin). This strategic partnership includes the development of education, training curriculum, training programs, competency certification and industry consulting 4.0 research assessment for GAPMMI members which will last for the next three years until 2025.

The learning material related to digital transformation which includes studying Agile Manufacturing, Efficiency Facilities and Resilient Supply Chain. This collaboration in developing digital competencies for Mamin's human resources is motivated by the commitment of national food industry players in efforts to accelerate digital transformation to face future challenges and increase competitiveness in the global market.

During these three years of cooperation, Schneider Electric and GAPMMI are targeting to train professionals in the field of engineering OT, operations and IT personnel.

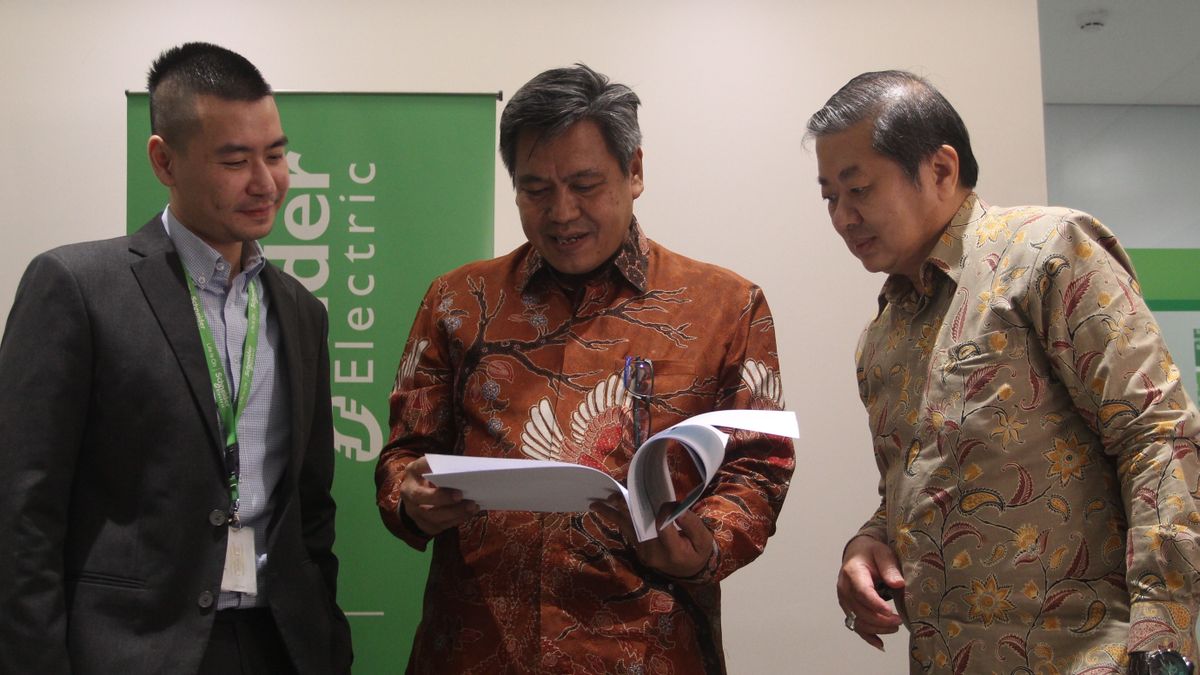

The announcement of the GAPMMI and Schneider Electric collaboration was conveyed in a media discussion activity with the theme Smart Mamin Industrial Transformation & Sustainable in Strengthening Food Security from the Global Crisis which presented speakers including Mr. Putu Juli Ardika, Director General of Agro Industry, Ministry of Industry of the Republic of Indonesia; Mr. Adhi S. Lukman, General Chairperson of the Indonesian Food and Beverage Producer Association (GAPMMI); and Mr. Martin Setiawan, Business Vice President Industrial Automation Schneider Electric Indonesia.

Adhi S. Lukman in the discussion emphasized the importance of efforts to accelerate comprehensive digital transformation throughout the supply chain and clean energy transition, which is supported by human resources that have digital literacy, economic climate, geopolitical and conducive investment, as well as a global food ecosystem that is collaborative in realizing food security and sustainability that has a positive impact on social and environmental.

"The world's population is estimated to reach 9.45 billion people by 2045, of which 319 million people come from Indonesia. You can imagine that every year the world's population will continue to grow, while we are also facing a crisis in the supply of food raw materials due to climate change. The consumers will also be increasingly critical of the products they consume both in terms of quality, added value offered, and environmental impact," said Adhi Lukman, in Jakarta, Thursday, February 16.

"Therefore, food and beverage producers need technology that can integrate and provide comprehensive visibility of each supply chain system life cycle starting from the supply of raw materials, production process, packaging, distribution to the hands of consumers. This technology requires skilled experts in operating it. This human resource development is the focus of GAPMMI at this time in supporting our members," explained Adhi.

Furthermore, as an industry that has proven to have a high resistance to the impact of the pandemic and global uncertainty, the achievements of the national food and beverage industry in the international market are even more brilliant.

Based on data from the Ministry of Industry, exports of food and beverages including palm oil reached US$48.61 billion in January-December 2022. Meanwhile, imports amounted to 16.52 billion in the same period.

Overall, the food and beverage industry grew 4.90 percent (yoy) and became the largest contributor to the GDP of the non-oil and gas processing industry in 2022, by 38.35 percent. Putu Juli Ardika, Director General of Agro Industry, Ministry of Industry of the Republic of Indonesia said that the government will continue to make various efforts to encourage the competitiveness of the food and beverage industry in the country, including ensuring the availability of industrial raw materials to support the production wheels.

"This guarantee is contained in Government Regulation Number 28 of 2021 concerning the Implementation of the Industrial Sector which ensures that the industry can obtain raw materials through the commodity balance. In terms of accelerating digital transformation, we provide facilities that include the implementation of self-assessment of INDI 4.0 Readiness Index (INDI 4.0) with a target of 800 companies in 2022 and 2023, and continued with technical guidance on industrial transformation 4.0 for managers and engineers, as well as the implementation of industry 4.0 in stages," said Putu.

Martin Setiawan, Business Vice President of Industrial Automation Schneider Electric Indonesia said that digital transformation in the food and beverage industry is quite complex considering that this transformation must cover three focus areas, namely Agile Manufacturing, Efficiency Facilities, and Resilient Supply Chain. Integration of the three areas is possible with the use of Industrial Internet of Things and open, collaborative and software-based automation technology.

"To be able to maximize the potential of digitization, it takes the ability of human resources to operate it. Not only technical operating capabilities, but also cognitive, including creativity, complex problem solving, critical, analytical and innovative thinking, and leadership. These aspects will be the focus on the development of education and the learning curriculum that will be formulated together with GAPMMI," said Martin.

The signing of the GAPMMI and Schneider Electric collaboration was carried out at the end of 2022. In addition to developing curriculum and training, GAPMMI members can also see firsthand the digitization practice at smart factory Schneider Electric in Batam and Cikarang, exchange of experts, and consultation.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)