JAKARTA - The Ministry of Public Works and Public Housing (PUPR) has completed the construction of the Kaca Seruni Point Bridge in the Bromo-Tenggger-Semeru National Tourism Strategic Area (KSPN), East Java, this year.

To test the performance of the structure and safety of the bridge, the Ministry of PUPR conducted a load test on the Seruni Point Glass Bridge (prototype).

Later, this trial will provide security and safety guarantees for tourists after being fully operational.

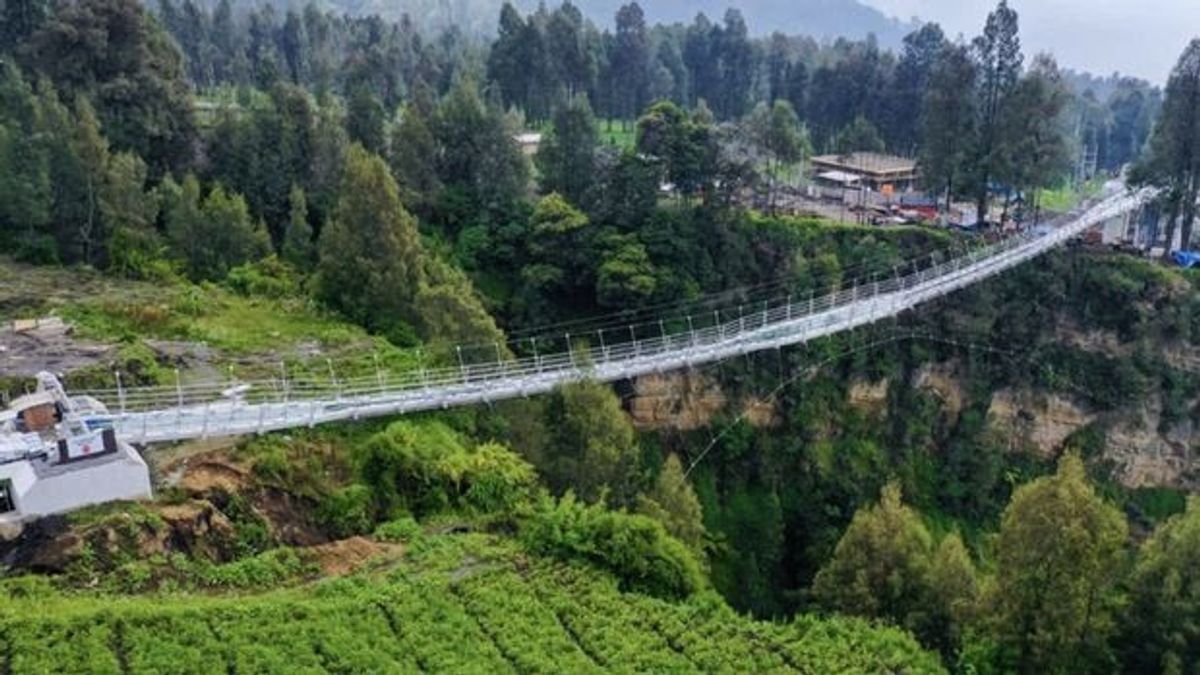

The presence of this glass bridge is an adrenaline tourism destination that connects Seruni Point Tourism Terminal with the Shuttle Area with views of Mount Bromo, Mount Batok and Mount Semeru.

With this bridge, it is hoped that it can increase tourist visits to KSPN Bromo-Tenggger-Semeru.

PUPR Minister Basuki Hadimuljono said infrastructure development at each KSPN is planned in an integrated manner, starting from regional planning, roads, supply of raw water and clean water, waste management, sanitation, to repairing population housing through a master plan for infrastructure development.

"The Kaca Seruni Point Bridge stretches 120 meters above the ravine with a depth of about 80 meters," Basuki said in a press statement, as quoted on Monday, January 9.

"This bridge is classified as a pedestrian suspension bridge (suspended cable) with a floor/deck structure in the form of layered safety glass (laminated glass) with a thickness of 12 mm each and is tightened using a vinyl interlayer layer," he added.

Meanwhile, the Head of the Geotechnic Tunnel and Structure Center (BGTS) of the Ministry of PUPR, Fahmi Aldiamar, said that the load test on the Seruni Point Glass Bridge was carried out using several instruments to obtain data on the performance of the structure and steel wires on the bridge.

One of the instruments used is Total Station (TS) to measure displacement or shift the benchmark when the bridge is crossed by human burdens.

The glass bridge loading test is carried out using sacks filled with sand weighing 70 kg or representing the weight of one adult.

The sacks are placed on the floor of the bridge with a distance of 75 cm each with a total weight of seven tons or the equivalent of 100 people.

The weight is known to be ten percent of the bridge-resistant power design.

"The first surplus in testing the load of the glass bridge is carried out with a weight of 0 percent. Second, testing using a load weight of 50 percent, the third is tested with a load weight of 100 percent. Furthermore, testing again with a load weight of 50 percent and finally testing with a load weight of 0 percent," said Fahmi.

In addition to measuring the deployment using the Total Station instrument, Fahmi explained that the loading test was also carried out to measure the performance of steel cables supporting the bridge and steel frames.

"BGTS uses accelerometers and gauge strains to measure the frequency of the structure and strain of the cable," he said.

As for the glass power testing, his party has conducted laboratory tests belonging to BGTS in Bandung, West Java.

According to Fahmi, the laminated tempered glass used has been tested in the laboratory and the results are very strong.

"It will not immediately break into pieces when there is damage, but shards in the form of glass cubes," he said.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)