JAKARTA - Intel CEO Pat Gelsinger estimates the reduced supply of chips will last more than a year. The shortage of "chips" stems from a lack of raw material supply to make semiconductors.

The decline in global production was also influenced by the prolonged COVID-19 pandemic. Including the trend of working and remote activities, which make it difficult for factories to assemble many electronic devices.

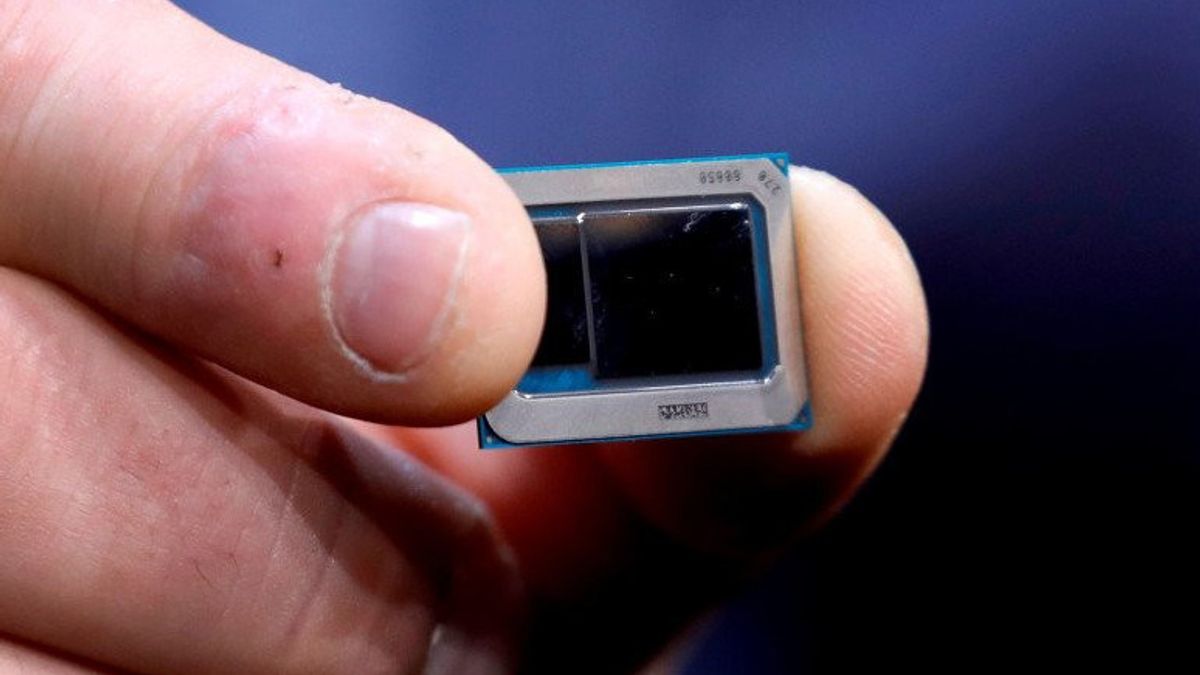

"While the industry has taken steps to address short-term constraints, it will still take several years for ecosystems to overcome capacity, substrate and component shortages," said Pat Gelsinger.

Intel also announced in March 2021 that it was investing $20 billion to expand its reach with chip manufacturing at two locations in Arizona.

Chips produced at the new location are also planned to be sold to other parties.

"We plan to expand to other locations in the US and Europe, ensuring a sustainable and secure semiconductor supply chain for the world," said Pat.

Intel can also be said to have entered and competed against two other giant chip manufacturing companies from mainland Asia, namely Taiwan Semiconductor Manufacturing (TSMC) and Samsung Electronics from South Korea.

Both of them are now the leader of the chip supply market and become the provider of sophisticated chip needs and spread in two thirds of the world.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)