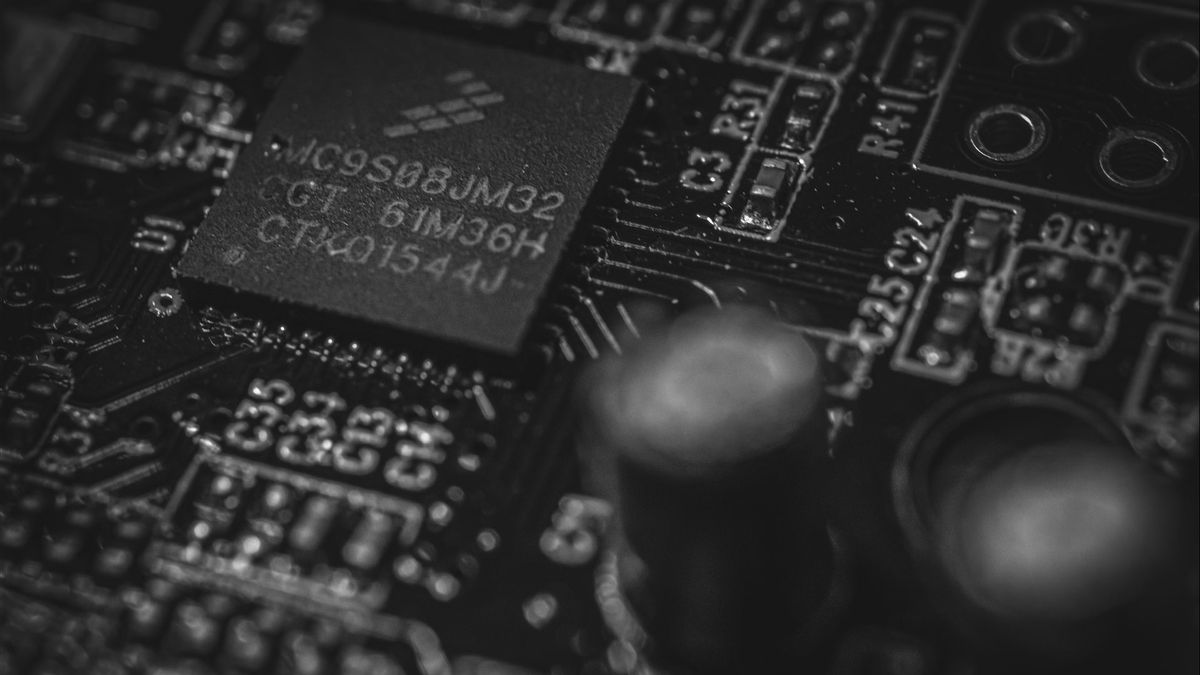

JAKARTA - Most of us may not realize that the world of technology is in trouble. It is the chip, which is at the core of all digital products around us, whose supply is running low. The tech world is experiencing "Chipageddon." What is it and how does it affect us?

What is clear, if the chips run out, no more production will be carried out. The chip shortage situation has been in the picture since last year, when gamers struggled to buy a new graphics card, Apple staggered releasing its iPhones, and Xbox and PlayStation consoles failed to keep up with demand.

Just before Christmas, the Chipageddon concern grew. The car industry this time is feeling the worst impact. New technology cars, on average, consist of more than a hundred microprocessors. And manufacturers can't have all of them.

Since then, technology companies have warned one by one that they too are facing a problem. Samsung is struggling to fill orders for memory chips it makes for its own and other people's products.

And Qualcomm, which makes the processors and modems that power many of the leading smartphones and other consumer devices, has the same problem.

Impact of a pandemicLike many other failures in the world, the cause is partly the corona virus. Kuncitara in various countries triggered an increase in sales of computers and other devices.

The increase occurred with the habituation of people working from home or those buying new devices and consoles to fill their break time.

The auto industry, meanwhile, initially saw a large drop in demand and cut orders. As a result, chip makers shifted their production lines.

But then, in the third quarter of 2020, auto sales were roaring back faster than anticipated, while the demand for consumer electronics continued.

5G infrastructureApart from that, the start of the 5G era also had an impact. The rollout of the 5G infrastructure adds to the demand for chips. With the current conditions, producing more is not easy.

"It takes about 18 to 24 months to open a factory after they start operating," said analyst Richard Windsor, quoted by the BBC, Saturday, February 6.

"And even after you create one, you have to adjust it and get the result, which also takes a little time.

"It's not something you can just turn on and off."

Chinese tech firm Huawei placed a large order to build up a stockpile of chips before US trade restrictions blocked it from ordering more.

In contrast, the auto industry has relatively low margins and tends not to stockpile on supplies, which now makes it very lagging behind.

Recently, TSMC and Samsung, the leading chipmakers, have spent billions acquiring an incredibly complex new 5-nanometer chip manufacturing process down to the speed to support cutting-edge products. But analysts say more broadly, the sector is suffering from a lack of investment.

"Most second-tier foundries have recorded poor earnings, low margins and high debt ratios over the past few years," said a recent report from Counterpoint Research.

"From a profitability perspective, building a new plant for a smaller foundry is difficult to consider."

And many of these chipmakers will instead respond to extra demand by increasing their prices.

The English, Chinese, Japanese, Arabic, and French versions are automatically generated by the AI. So there may still be inaccuracies in translating, please always see Indonesian as our main language. (system supported by DigitalSiber.id)